(Best AI Tools)The manufacturing sector is undergoing a significant transformation, largely driven by the integration of Artificial Intelligence (AI). AI in manufacturing is enhancing efficiency, reducing costs, and improving product quality. This blog post aims to explore some of the best tools for AI integration in manufacturing, highlighting how they can revolutionize production processes.

1. Siemens MindSphere: Pioneering Industrial IoT

Siemens MindSphere stands at the forefront of integrating AI in manufacturing. It is an open cloud-based Internet of Things (IoT) operating system that connects physical infrastructure to the digital world. MindSphere collects and analyzes data from machines and physical systems, enabling manufacturers to optimize operations, predict maintenance needs, and improve overall efficiency.

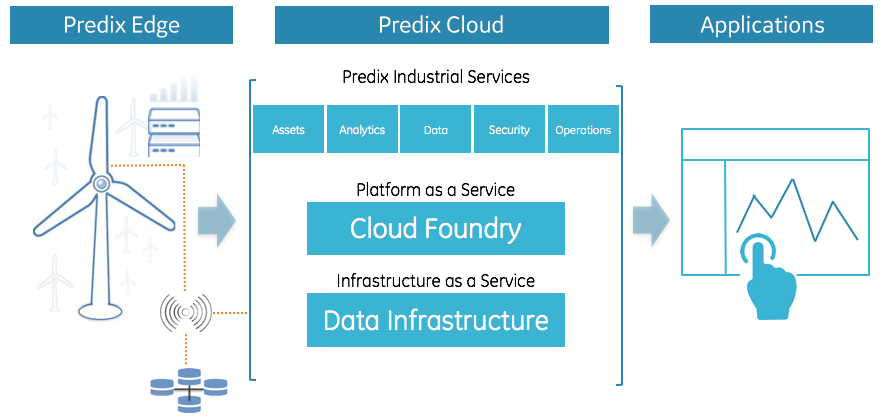

2. General Electric (GE) Predix: Industrial Analytics Platform

GE’s Predix platform is designed specifically for industrial data and analytics. It uses AI and machine learning to analyze data from industrial machines, providing insights to optimize machine performance, enhance reliability, and reduce downtime. Predix can be used to predict equipment failures and schedule timely maintenance.

3. Rockwell Automation: Smart Manufacturing Solutions

Rockwell Automation offers a range of AI tools that facilitate smart manufacturing. Their solutions include AI-powered analytics for predictive maintenance, process optimization, and supply chain management. Rockwell Automation’s tools help in reducing operational costs and improving productivity in the manufacturing process.

4. IBM Watson IoT: AI for Cognitive Manufacturing

IBM Watson IoT provides AI solutions specifically tailored for manufacturing. These solutions include cognitive visual inspection, equipment effectiveness, and process optimization. Watson IoT’s AI capabilities can analyze data from various sources, including sensors and equipment, to enhance decision-making and operational efficiency.

5. SAP Leonardo: Integrating AI with ERP

SAP Leonardo integrates AI into the manufacturing process by enhancing Enterprise Resource Planning (ERP) systems. It offers machine learning and analytics capabilities to process large volumes of operational data, improving supply chain management, production planning, and asset maintenance.

6. KUKA: Robotics and Automation

KUKA is renowned for its advanced robotics and automation solutions, integrated with AI technologies. These robots are used in various manufacturing processes, including assembly, welding, and material handling. KUKA’s AI-enabled robots can adapt to changing environments and tasks, increasing flexibility and efficiency in manufacturing.

7. PTC ThingWorx: Industrial Innovation Platform

PTC ThingWorx is an industrial innovation platform that combines AI with IoT. It provides tools for predictive maintenance, operational monitoring, and process optimization. ThingWorx’s AI algorithms analyze data from connected devices and machines to anticipate equipment failures and optimize manufacturing processes.

8. Autodesk Fusion 360: AI in Design and Engineering

Autodesk Fusion 360 integrates AI in the design and engineering phase of manufacturing. Its generative design capabilities use AI to propose the most effective designs based on materials, manufacturing methods, and performance requirements. This tool significantly reduces the time and cost involved in product development.

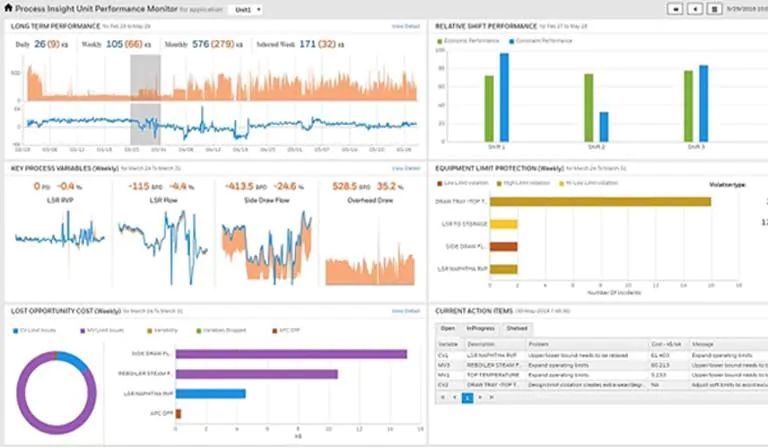

9. Honeywell Connected Plant: Performance Insights

Honeywell’s Connected Plant uses AI to provide insights into manufacturing performance. It analyzes data from plant operations to identify areas for improvement in efficiency and productivity. Connected Plant also offers solutions for predictive maintenance and process optimization.

10. Microsoft Azure AI: Versatile AI Solutions for Manufacturing

Microsoft Azure AI offers a range of AI tools that can be applied in manufacturing. These include machine learning services, cognitive services for intelligent analysis of visual and auditory data, and AI-driven insights to optimize manufacturing processes and supply chains.

Conclusion

The integration of AI in manufacturing is not just a futuristic vision; it’s a present reality that is reshaping the industry. These AI tools are enabling manufacturers to optimize their processes, reduce costs, and produce higher quality products. By leveraging AI, manufacturers can gain significant competitive advantages, such as increased efficiency, improved product customization, and enhanced predictive maintenance capabilities. As AI technology continues to evolve, its potential to further transform the manufacturing industry is boundless. This digital revolution is paving the way for smarter, more efficient, and more sustainable manufacturing practices.